We’re excited to announce a series of online ‘Ask me Anything (AMA)’ sessions for 2026. We’ll cover a range of EM imaging subjects and techniques, all designed to educate but also to open up the floor to participants keen to discuss specific questions, pain points or advice. Professor Nigel Browning, Chair of Electron Microscopy at Liverpool University will host the sessions, and will be joined by some of the Worlds leading scientists from the world of EM. You can find the dates and sign up in advance below.

Session #1 – What to expect in the Compressed Sensing Landscape for Electron Microscopy in 2026 – Completed

Professor Nigel Browning looks at the key advancements from 2025 and what to expect in 2026.

We’ll start by looking over the past 12 months; what the key advancements have been, which applications have seen the biggest wins, and the key new research it’s all enabled.

We’ll then look forward at new technologies likely for 2026, where users are going to be focussing their investments and what new experiments and research we can expect to see in the next 12 months as a result.

Bring along your questions, discussion points and holy grails for 2026 as we’ll open up the floor at the end of the session.

Session #2 – SEM Imaging – Featuring guest speakers from the world of Volume EM and Materials Science

23rd April @ 4pm

We’ll be joined by leading scientists working in the field of SEM Imaging. They’ll reveal the advancements they’re making, the technologies they’re most excited about and how other users can optimise their experiments.

Bring along your questions, pain points and experiences as we open up the floor on the topic of SEM Imaging.

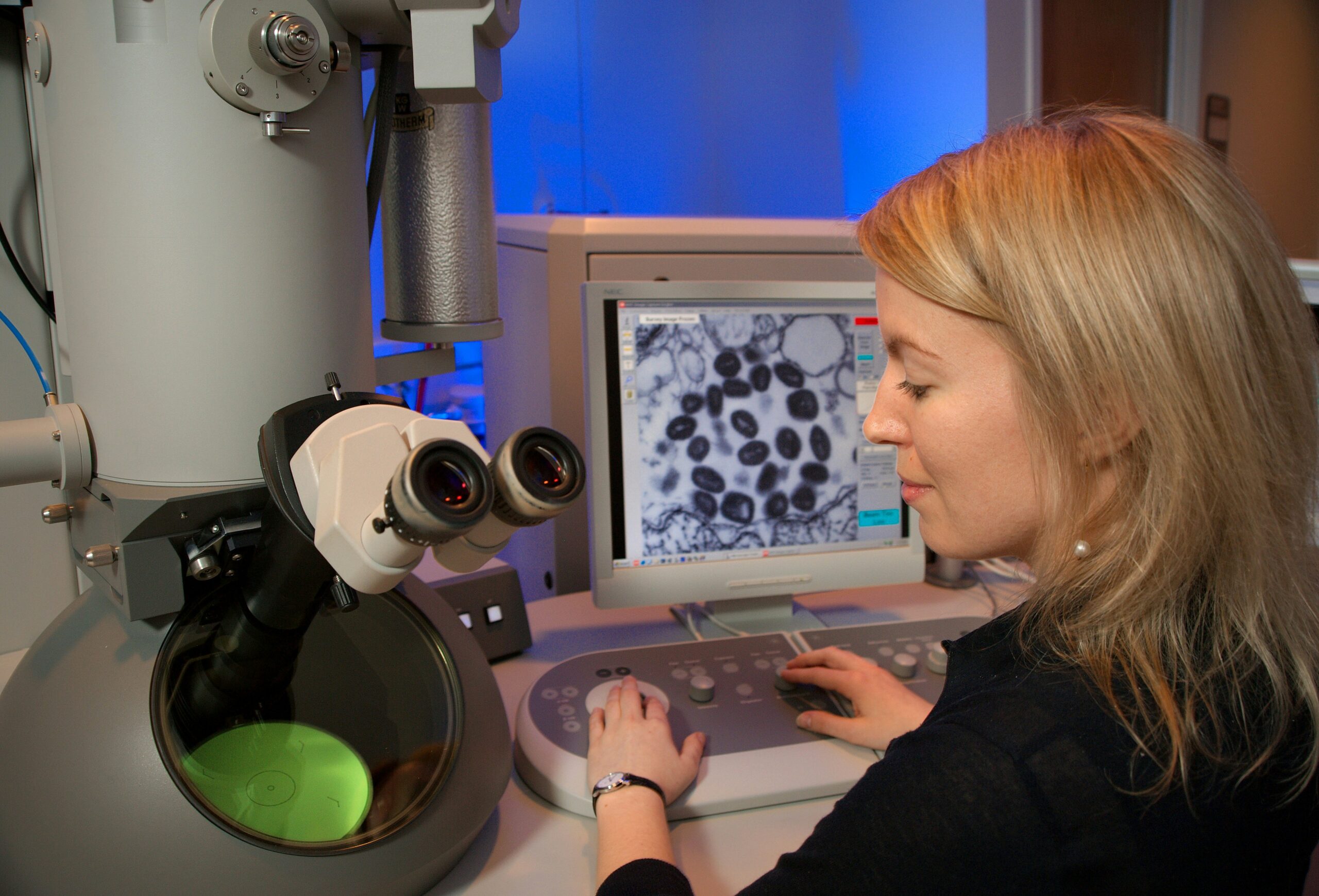

Session #3 – STEM Imaging – the new world of 4D STEM, EELS and EDS

September (exact date TBC)

There are huge advances happening in the world of STEM.

In 4D STEM experiments you can now make live reconstructions using subsampled data, enabling real time adjustments. While you’re on the microscope, you can change the focus, area or location, and optimize it to get the best quality image.

And the same technology is about to hit EELS and EDS too.

Find out what this means for STEM experiments across various industries and bring your questions and pain points along to put to Professor Nigel Browning and other leading scientists from the world of STEM.

Session #4 – Compressed Sensing & Alternative Imaging: A review of 2026 and preview of 2027

December (exact date TBC)

We host our annual review of the biggest change makers and technologies from the past 12 months and look ahead to the planned and anticipated innovation set for 2027.