Let’s take an in depth look at lowering beam dose exposure to protect sample integrity and imaging quality in Electron Microscopy

Introduction

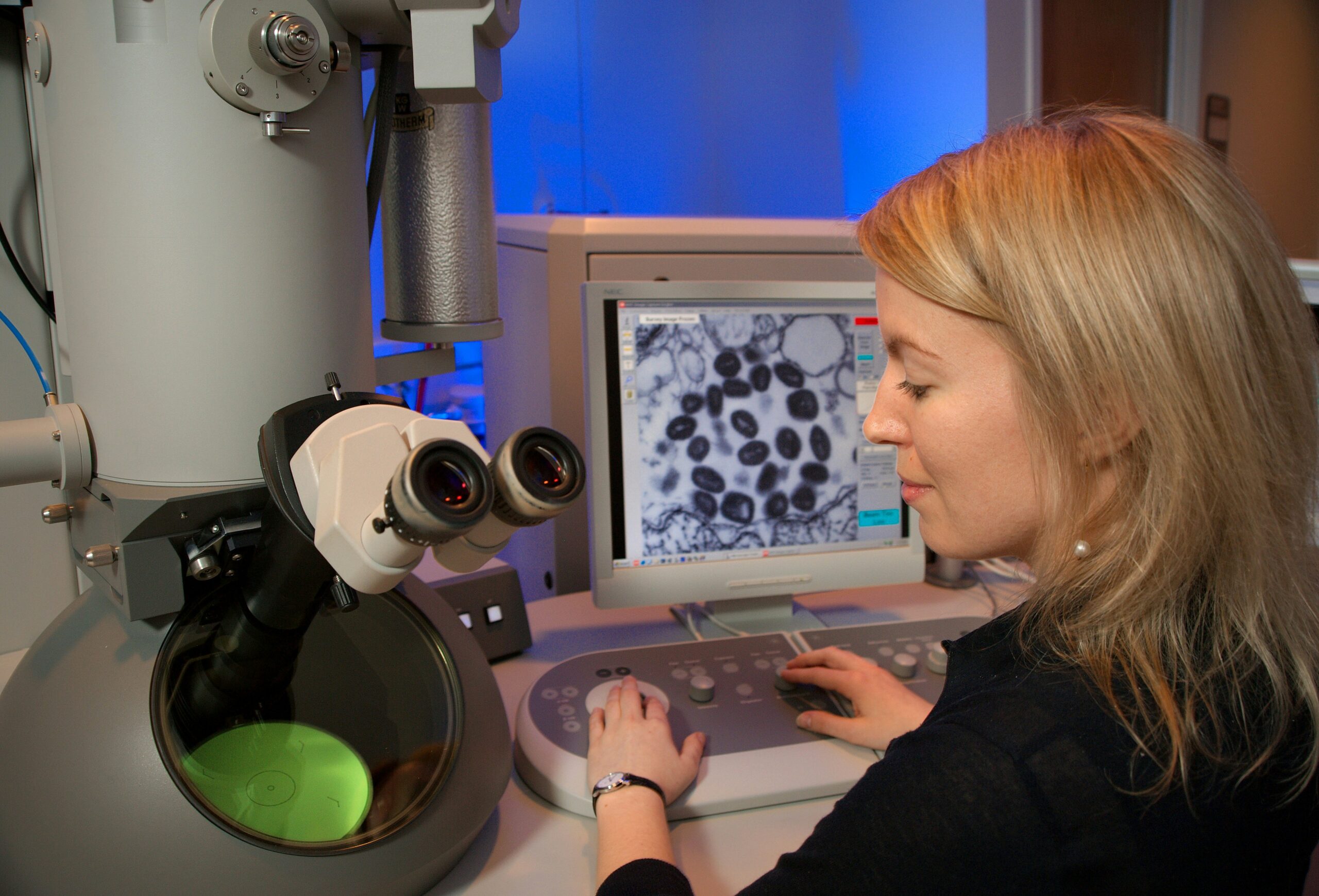

Beam damage of the sample is one of the biggest challenges in Electron Microscopy, affecting the quality of results, limiting the types of samples and experiments that can be studied, and in many cases altering the actual structure of the materials being analysed.

What is ‘dose’ in Electron Microscopy?

The term ‘dose’ in electron microscopy refers to the number of electrons that interact per area with a sample during imaging or analysis. Flux refers to the dose rate i.e. per unit of time. Higher doses (and fluxes) can improve image contrast and resolution, but they also increase the risk of changing, charging and/or damaging the sample. The dose is typically measured in electrons per square angstrom (e⁻/Ų), fluxes are (e⁻/Ų·s), and managing it is a crucial part of experimental design.

Beam damage occurs when the energetic electrons used for imaging interact with the atoms in a material, causing physical or chemical changes. These interactions can break chemical bonds, displace atoms, induce heating, and even cause mass loss. For liquid or gas phase experiments this dose can completely alter what you are trying to measure.

Which samples and industries are most affected

Beam-sensitive samples, such as biological tissues, polymers, and certain nanomaterials, are especially vulnerable to high dose and beam damage. Industries using these types of samples include semiconductors, batteries, energy storage and catalysis i.e. critical industries for mankind’s development.

How SenseAI reduces beam damage in Electron Microscopy

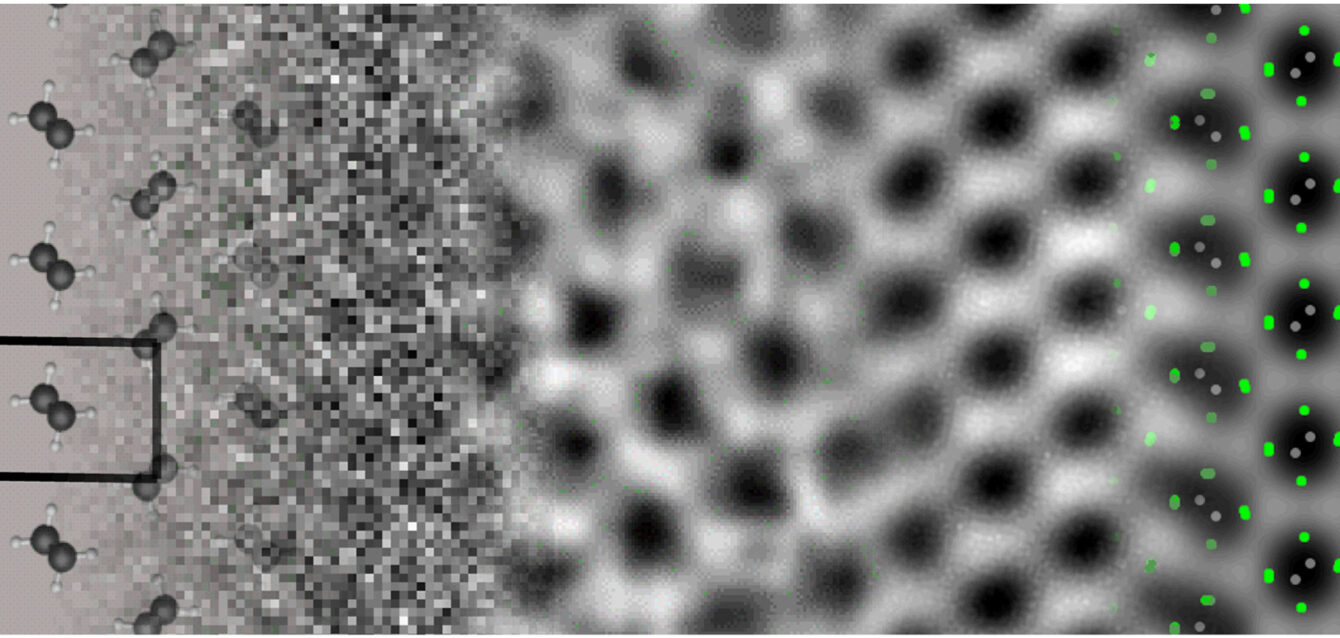

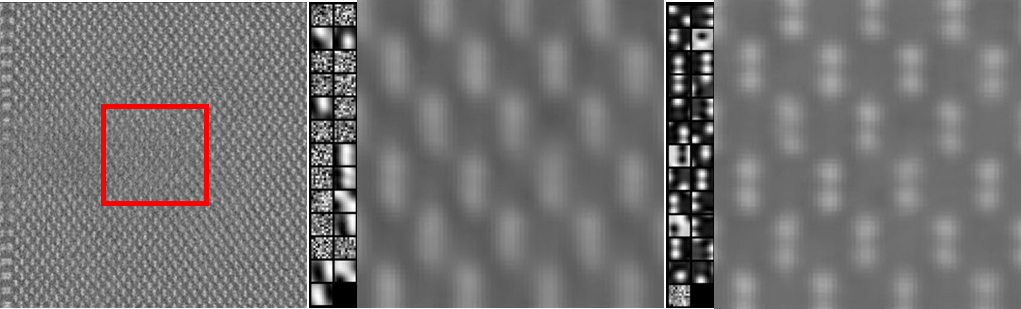

SenseAI reduces dose (and hence beam damage) by up to 100x and can therefore preserve sample integrity in even the most sensitive environments. We achieve this by using a compressed sensing technique in Electron Microscopy called subsampling and then inpainting.

Subsampling is a core component of the SenseAI workflow and technology and involves the deliberate formation of incomplete datasets. By sampling just a fraction of the data, such as only a few percent of the pixels within an image, subsampled data can be produced and processed with much reduced charging effects and beam damage. This benefits all samples in different ways, from regular material samples to liquid or gas experiments. In life sciences it assists resin embedded samples and also massively enables cryo samples and cryo volume EM samples where the beam can melt the ice that the sample is frozen within.

An example of how SenseAI is reducing beam damage in practice

The Centre for Ultrastructural Imaging (“CUI”) is the central electron microscopy unit at King’s College London, one of the leading EM hubs in Europe for life sciences. It has expertise in life science and biological samples using Cryo-FIB (Focused Ion Beam for cryogenically prepared samples). The major challenges they encounter are mostly relating to charging artifacts and sample stability.

Professor Roland Fleck, Director of Centre for Ultrastructural Imaging says: “Our work is extremely beam sensitive. If you put too much dose in, you will de-vitrify your sample. So as a result, it’s a challenging sample to work with. And that’s why we approached SenseAI.

“The compressed sensing approach by SenseAI essentially acquires smaller data volumes, which helps with the post processing of data. But one of its major advantages is if I’m only collecting, say, 20 or 25% of the field of view, I’m essentially working four or five times faster. So, the time required to complete an entire volume is significantly reduced, which is less stressful on the sample, less stressful on the instrument, less stressful on the operator, and generates much higher success rates.”

High dose and beam damage present significant challenges in electron microscopy, often dictating the limits of what can be observed and analysed. But by applying SenseAI, EM users are now able to work with samples they’ve simply not been able to work with previously and can analyse data in real-time knowing their sample integrity is preserved. Talk to one of our team about how SenseAI can support your beam sensitive research.