Professor Roland Fleck, Director of the Centre for Ultrastructural Imaging talks about how they use SenseAI for faster, lower dose, lower data imaging.

Challenges

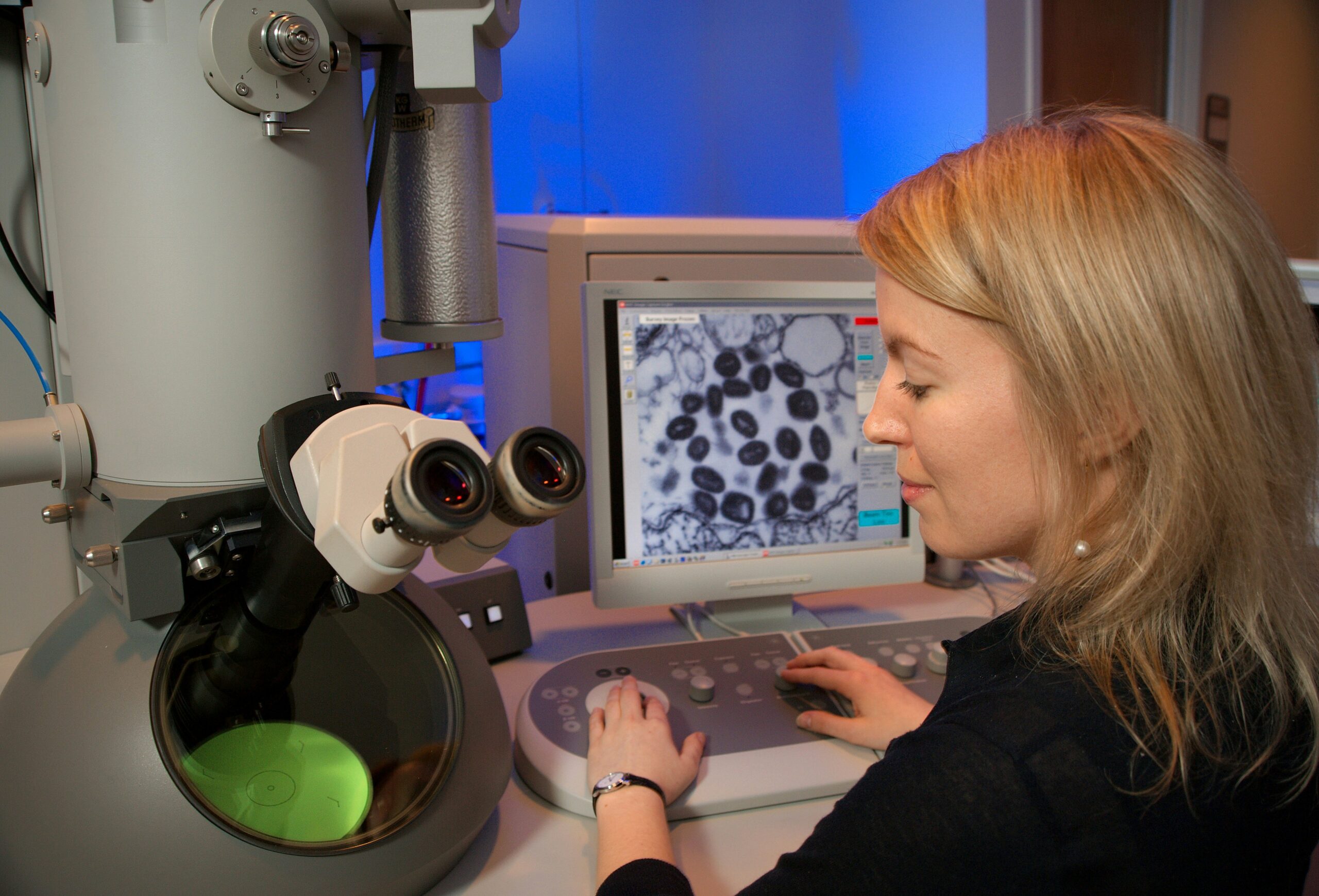

- Sample Stability – the major challenges we’ve encountered really relate to sample stability. Our preference is to work with vitrified biofix material, which is essentially frozen. It’s extremely beam sensitive. If you put too much dose in, you will de-vitrify your sample. It doesn’t have any introduced contrasting mechanisms. We don’t use heavy metals. So as a result, it’s a challenging sample to work with.

2. Data size – another major challenge for VEM (Volume Electron Microscopy), a rapidly developing field, is the size of the volume that users wish to achieve. Essentially, the bigger the volume, the more informative it is. However, the bigger the volume, the larger the dataset, which makes processing extremely challenging. In addition, the larger the volume you wish to acquire, the longer it takes. So we have a challenge in terms of total data volume and the time required to acquire the volume, which in itself puts a pressure on the microscope because it has to remain stable, functional, and operational for very long periods of time, possibly weeks at a time.

3. Speed and Cost – another challenge, particularly with focused ion beam scanning electron microscopy, and the same would apply to plasma sourced instruments, is that a surface of the milling material is essentially being used, each time we turn on the instrument. That comes with a significant financial cost. If I can acquire the same volume in a quarter or a fifth time, my source lasts four to five times longer. That’s quite a significant difference in terms of the total cost to generate a single volume.

4. Noise – Cryo sample transfer can be conducted cleanly and robustly if your laboratory is sufficiently well equipped. The FIB systems are also extremely stable and well engineered. Really, the challenge is handling the vitrified sample and the difficulty of actually imaging it and generating sufficient signal to noise to allow you to reconstruct your volume and analyse it in a meaningful way.

Professor Roland Fleck, Director of the Centre for Ultrastructural Imaging. King’s College London says:

“One of the major advantages of SenseAI is if I’m only collecting 20 or 25% of the the the field of view by using the compressed sensing strategy, I’m essentially working four or five times faster than I can otherwise. Also, if I can acquire the same volume in a quarter or a fifth time, my source lasts four to five times longer. That’s a significant difference in terms of the total cost to generate a single volume.

“SenseAI is enabling us to reconstruct our volume and analyse it in a meaningful way. I can simply use SenseAI to speed up the entire process and and manage the the imaging part of the data

volume generated at the end of a a volume acquisition. It’s applicable to any scanning modality, as well as room temperature FIB SEM, serial block phase, or an array tomography if you’re using SEM to collect the data. SenseAI is also easily accessible to end users who are not a computational experts.“SenseAI opens up the avenues for compressive sensing and can essentially be routinely employed as an acquisition tool on on any microscope that’s suitably equipped.

“With the aid of SenseAI to help with signal to noise, damaging artifacts, charge balancing, and speeding up the entire process, you can envisage a situation where Cryo VEM becomes routinely practical and simple to apply within the laboratory environment.”