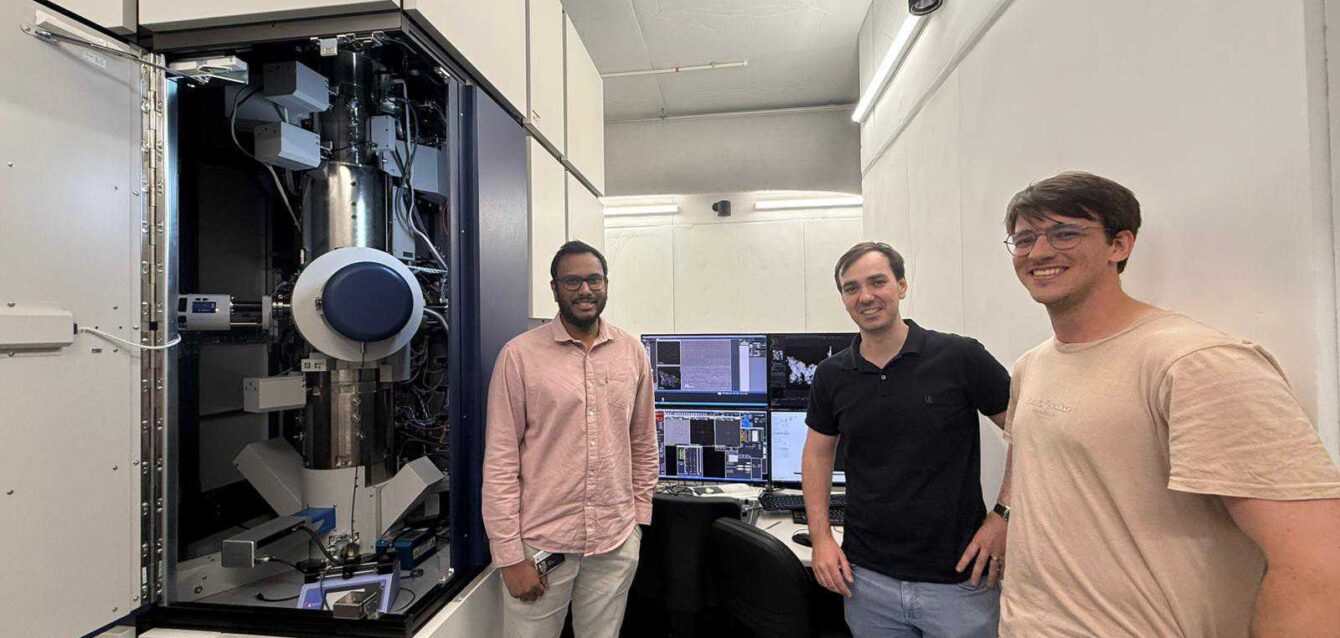

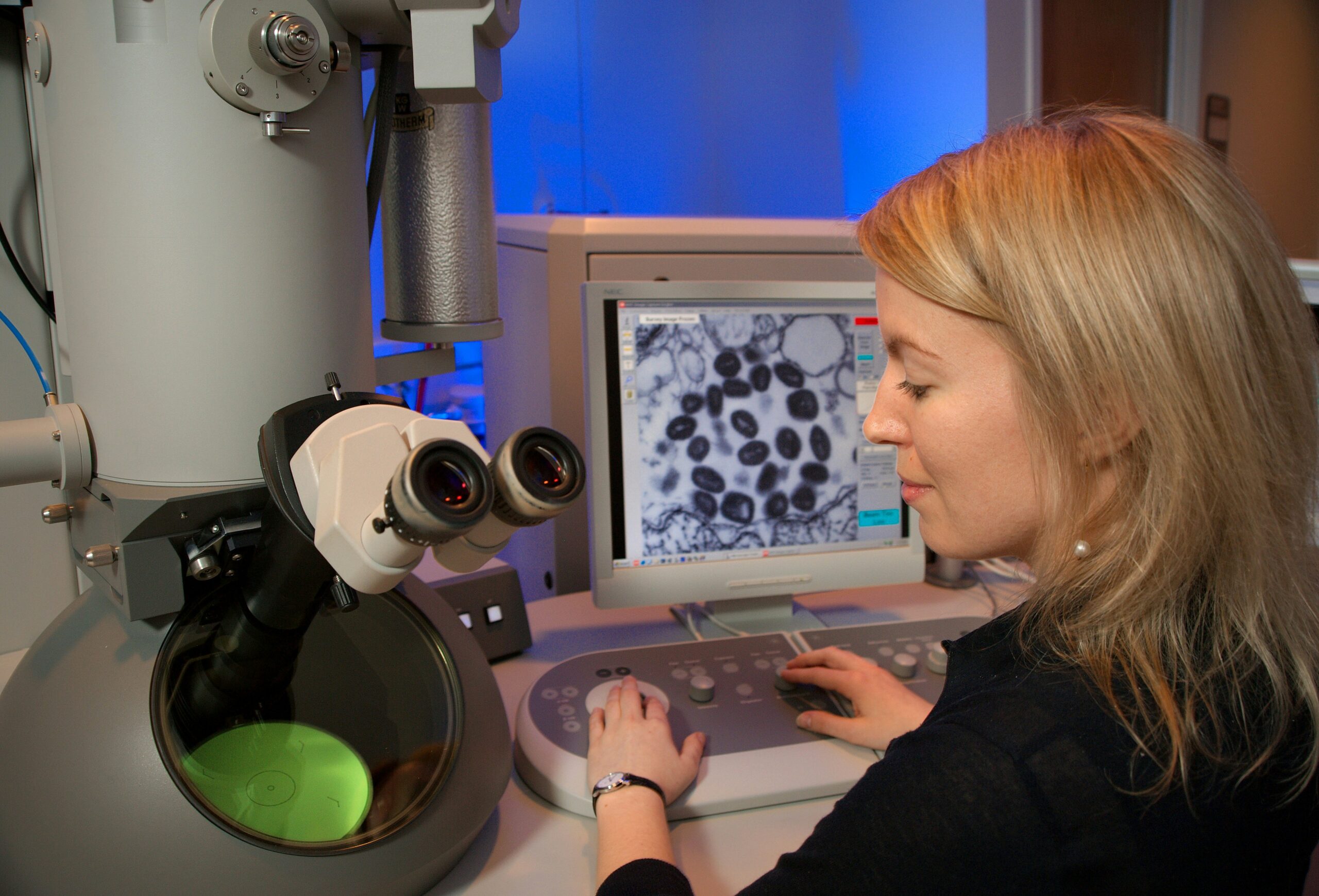

SenseAI imaging software has been installed at The Centre for Microscopy and Microanalysis (CMM) at University of Queensland. As a result, the centre will now be able to perform live 4D STEM and 2D STEM experiments on their Hitachi HF5000.

SenseAI’s compressed sensing technique generates high-quality images from only a fraction of the original pixels. Because it’s scanning up to 99% less data, it’s significantly faster – enabling adjustments to be made live on the microscope.

Beam damage of sensitive samples will also be a thing of the past for CMM as the software also reduces dose (and hence beam damage) by up to 100x. The centre will therefore be able to preserve sample integrity in even the most sensitive environments.

CMM have been keen followers of the founder of SenseAI, Professor Nigel Browning, and saw the software in action at a trade event last year. Because 4D STEM experiments will play such a significant role in the future of materials science analysis at CMM, the opportunity overcome the industry wide challenges of speed and high dose, whilst generating the same high-res images lead them to purchase the software.

Dr Danny Nicholls of SenseAI, part of the installation team, said: “It’s such a great facility at CMM and for SenseAI to be part of such a distinguished line-up of EM solutions is really exciting. The CMM team were great to work with and we can’t wait to start seeing the results of their supercharged 4D STEM experiments.”